Introduction

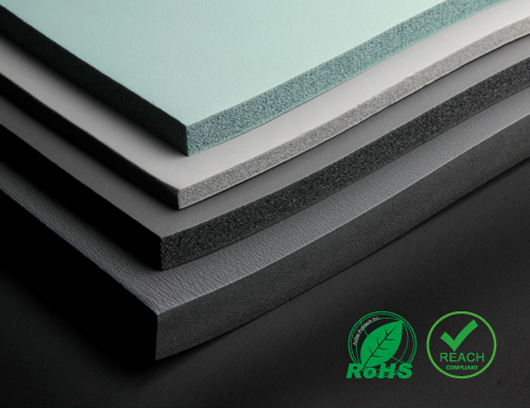

Yingsheng Energy Saving currently has a product series with multiple varieties and specifications to meet the needs of different customers in various industries. At the same time, in order to better serve customers, adhering to the customer service concept of "precision processing, professional service", we provide customers with tailor-made deep processing of a series of products: such as backing glue, cutting, stamping, compounding, slitting, etc.

Application

Self-Adhesive Backing

To meet construction and installation timeline requirements, a self-adhesive layer is added to the surface of the base material using a production line process such as machine rolling. During on-site application, the product only needs the kraft paper backing peeled off so the adhesive layer can be applied directly onto the pipe, significantly saving construction time.

Slitting

With brand-new high-precision rotary cutters, the accuracy reaches the millimeter level, meeting the market demand for insulation boards under 10mm in thickness. With thickness as low as 2mm, the outer layer is removed through slitting to enhance the sound absorption performance of the insulation material.

Stamping

Using die-cut stamping for production ensures products are mass-produced with precise, deviation-free dimensions. Based on customer drawings and designs, it solves problems such as complex geometric shapes during on-site construction and uneven manual cutting, ensuring stamped products are neat and consistent in appearance.

Lamination

High-performance polymer "Feibo" metal composite layers, fluorocarbon fiber layers, and reinforced aluminum foil composite layers are seamlessly fused with Winsulation rubber-plastic insulation materials using special processes. This significantly enhances various performance indicators of the rubber-plastic insulation, such as fire resistance, water vapor permeability resistance, tear strength, aging resistance, and aesthetics—making it an outstanding product in the category of composite rubber-plastic insulation materials.